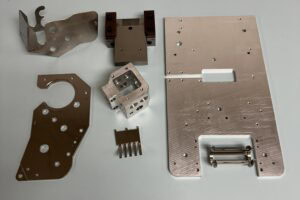

At Spring Mills Manufacturing, Inc., our machine shop services deliver precision, reliability, and performance on every job. Whether you need a single prototype or a high-volume production run, we handle every project with the same attention to accuracy and consistency. Our team of experienced machinists and engineers works with advanced equipment to produce parts that meet tight tolerances and demanding specifications.

We understand that the parts you rely on must meet exact dimensions and maintain consistent quality. That’s why our machine shop services combine skilled craftsmanship with modern technology to produce components that perform exactly as expected. From small industrial parts to large, complex assemblies, we focus on providing solutions that help your business run smoothly.