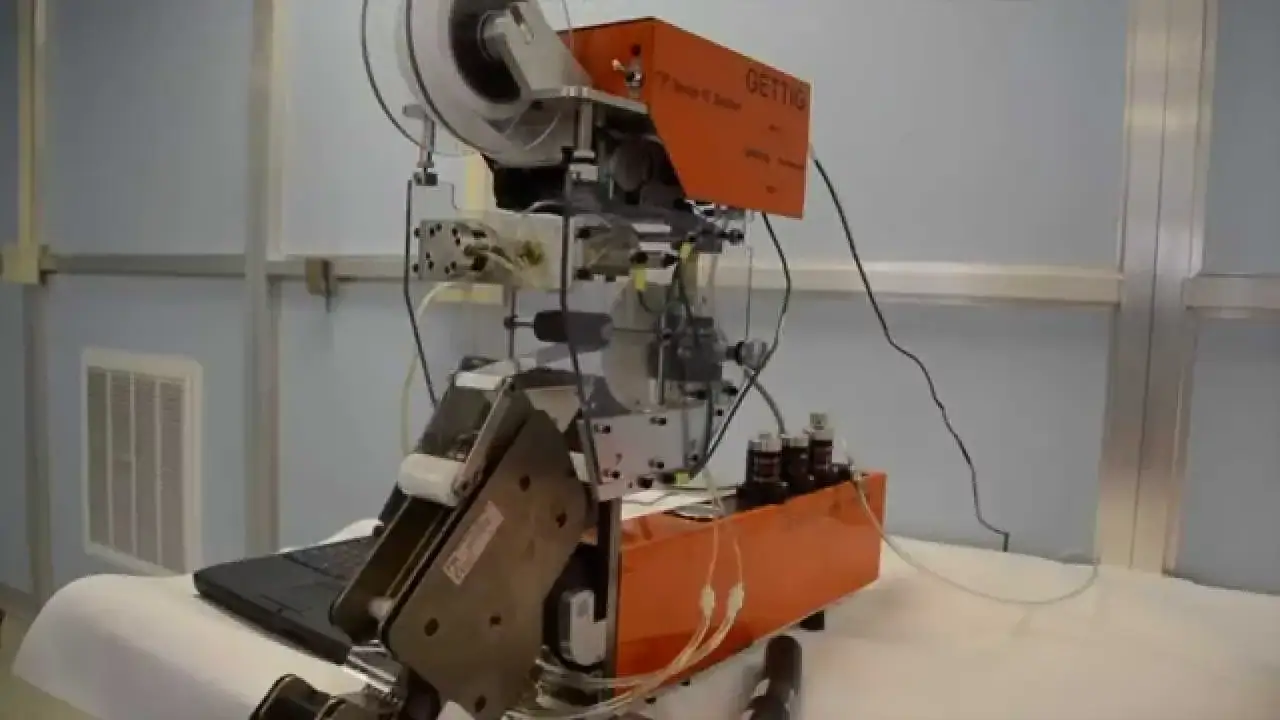

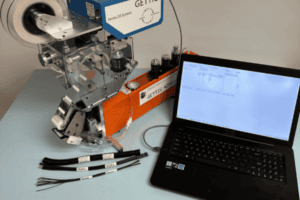

Semi-Automatic Labeling Machines

At Spring Mills Manufacturing, Inc., we are the exclusive manufacturer of the Gettig Spot Taping and Labeling Systems. Our labeling systems utilize a semi-automatic labeling mechanism and are capable of up to 600 applications per hour. Software is provided with each machine, allowing customers to create labels with company names, parts numbers, date codes, or other pertinent information. Labels are printed on paper or polypropylene roll stock. The labels are then wrapped with an over-laminate material consisting of polyester with an acrylic or silicone adhesive. Our labels have been proven against a myriad of chemicals include brake fluid, antifreeze, motor oil, and salt water and in temperatures from -40°C to 150°C.

Applications for the Gettig labeling system are not limited to wiring, and include an extensive list of components such as cables and hoses used in the automotive industry. Wires, cable, and hydraulic hoses between 0.050″ and 1.5″ can be labeled using this UL approved system. Simply put, no system can beat the efficiency, quality, and cost effectiveness of our labeling system. Systems can be customized for specific applications, including integration into existing in-line cutting systems. A variety of stock models are typically available for quick shipping, but specific systems can be quoted on a job by job basis. For more information about our semi-automatic wire labeling system, see the table below, or contact us directly.

Semi- Automatic Labeling System Capabilities

Semi-Automatic Labeling System

Labeling

Optional Integration into In-Line Systems

Customizable

Low-Maintenance

Reliable

Wiring

Hoses

Cables

Tubing

0.050″ to 1.500″

Paper

Polypropylene

Polyester

Vinyl

Acrylic

Silicone

Rubber

Up to 900 Applications per Hour

Antifreeze

Brake Fluid

Motor Oil

Salt Water

Transmission Fluid

Windshield Washer Fluid

-40°C to 150°C

Quoted on a Job by Job Basis

Expedited Service Available

Additional Information

Automotive

Electronic

Hydraulic

Medical

White Goods

Can Meet UL Standard 510C